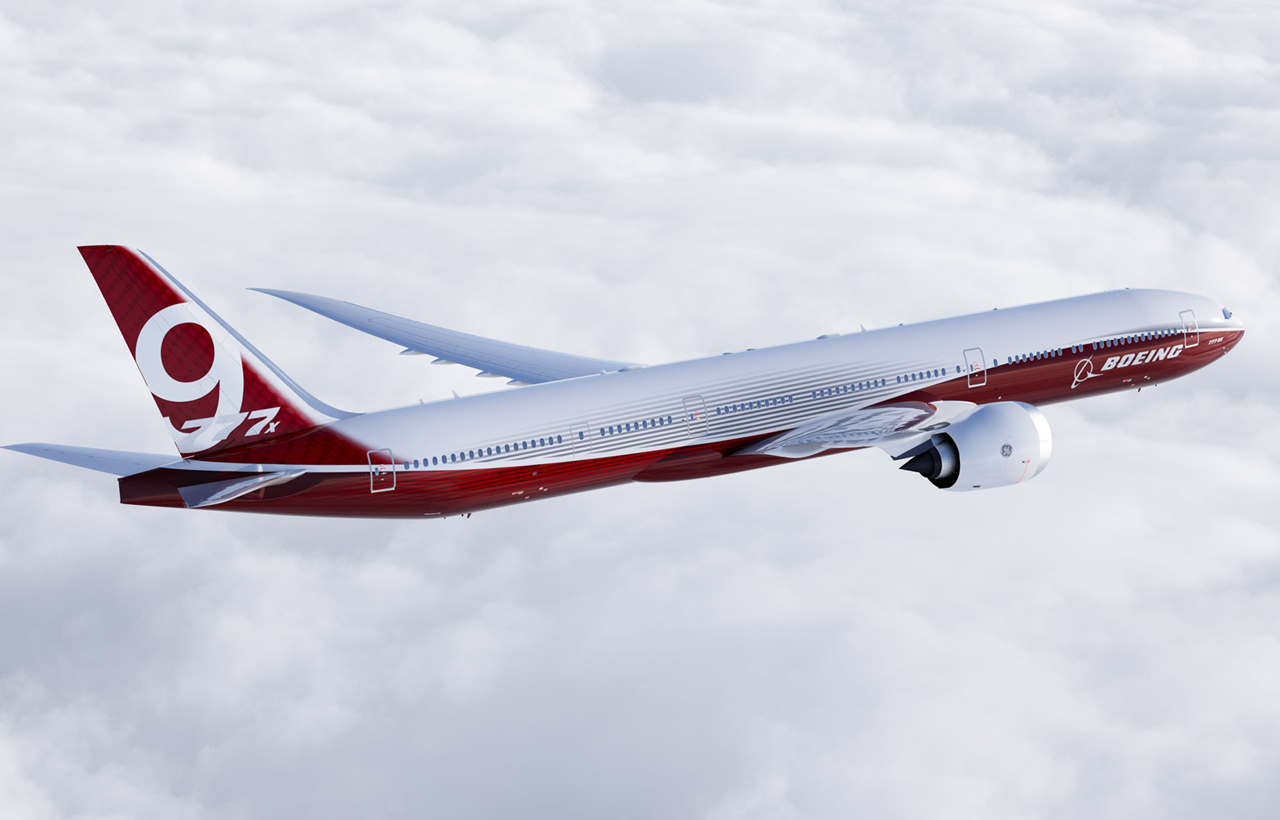

Boeing wants incentives from both its home state and its employees for its just announced 777X project. Due to workers not agreeing to cuts in benefits, assembly will likely be done elsewhere, possibly even outside the US. Everett, Renton, and the entire state of Washington have helped build Boeing into the mighty global corporation they are today. Now in order to save some money, Boeing is considering moving to other states or even other countries for 777X assembly.

- Boeing posted a record net loss of nearly $12 billion last year. It took a $6.5 billion charge in the fourth quarter against its 777X program, it's newest plane. The Covid pandemic is upending.

- Boeing took a pre-tax charge of $6.5bn for the 777X program. “We now anticipate that the first 777X delivery will occur in late 2023,” Calhoun said in a message to employees.

I found this article in the New York Times, and due to the focus being on the assembly of the next generation of the Boeing 777 (the so-called 777X), I found it intriguing. There already is an assembly line for the 787 in South Carolina. Some proposals to keep 777X work in Washington, but due to recent events, that may no longer happen.

That would add time, and costs, to the certification process. One way or the other, though, you’ll see the 777X in service soon. According to list prices, the 777X goes for up to $442.2 million a unit, although airlines almost always get discounts.

There is much more to this situation than is featured in the article, or in my comments, but even this limited scope is rather provocative.

Excerpts from the article:

The full column is linked above, and some excerpts are quoted below.

Compensation for assembly workers decreases:

What Boeing wants is very simple: to pay the people who make its airplanes as little money as it can get away with. It needs to do this, we’re told, to stay competitive. It has all the leverage, because enough states — and countries — are willing to give it everything it asks for. Who wouldn’t want a gleaming factory stuffed with jet assemblers, a payroll guaranteed for a generation?

Good work if you can get it, but pay cuts are always difficult to swallow

The machinists didn’t ask for hefty pay raises or new benefits as a condition to keep the much-promoted 777X production in this region. They just wanted to preserve what they had — jobs that could pay up upward of $80,000 a year, with a guaranteed pension.

Despite multiple issues such as 787 problems, CEO compensation grows

Boeing is on a roll, its stock at a record high despite the troubled rollout of its 787 Dreamliner, and the pay of its C.E.O. boosted 20 percent to a package totaling $27.5 million last year. It is not impelled, as the auto industry was five years ago, in the midst of bailouts and cutbacks. Boeing could afford to be generous, or at least not onerous.

Boeing will likely leave their home state in search of cheaper labor costs:

In the wake of the machinists’ rebellion, Boeing is likely to move. “We’re left with no choice but to open the process competitively and pursue all options for the 777X,” said Boeing’s commercial airplanes C.E.O., Ray Conner, after the vote.

Washington offered incentives to keep Boeing assembly in state

The state agreed to subsidize Boeing to the tune of $500 million a year over 16 years. That’s twice what the state gives to the University of Washington, the region’s flagship college, long an elevator to the middle class.

More information on the initial orders for the 777X at the Dubai Air Show is here. Also, more details on some other options for assembly of the 777X including locations outside the US.

What are your thoughts?

Many of the 787 Dreamliner’s issues could be linked to the countless contractors for components being sourced from all over. Would you feel safe flying on an airplane assembled by less experienced workers? What about outside the current most common aircraft manufacturers in North America, Western Europe and Brazil?

Read This Next

Boeing closed the books on a bruising 2020 by announcing another unpleasant surprise on Wednesday: a $6.5-billion hit from delays to its new 777X plane that exacerbated the aerospace giant's annual loss.

Boeing, which saw its revenues ravaged by the commercial airline downturn sparked by the COVID-19 crisis and the 20-month grounding of its 737 MAX model, now expects first deliveries of the wide-body 777X in late 2023, compared with the earlier timetable of 2022.

777x Development Cost

The accounting for the 777X prolongation pushed Boeing's fourth-quarter loss to $8.4 billion, plunging its tally for all of 2020 to $11.9 billion in the red, its biggest ever annual loss.

Cost Of 777x

The past year was one of 'profound societal and global disruption which significantly constrained our industry,' said Chief Executive Dave Calhoun.

'The deep impact of the pandemic on commercial air travel, coupled with the 737 MAX grounding, challenged our results.'

In light of radically worsened market conditions, Boeing has taken a hacksaw to costs, announcing job cuts of some 30,000 employees over two years.

The company also completed a $25-billion bond offering to provide liquidity to ride out the downturn.

Boeing executives emphasized that they expect a long-term recovery in travel demand, but reiterated that it will take about three years for activity to return to pre-pandemic levels.

777x Cost

They cautioned that profit margins will be under pressure until demand returns and the company is able to ramp up plane production.

'I'm quite optimistic,' Calhoun said in a conference call with analysts.

'There's nothing about the market right now that has me switched off on that, but we are talking about 2023. It's going to take that long for us to sort of work our way out of the COVID world.'